Toward carbon-free

Tire Reinforcement MaterialsLIPPER NR100-18

Bio-rubber reinforced material LIPPER (NR100-18) is a masterbatch rubber with 18% cellulose nanofibers highly dispersed in natural rubber.

Nanotechnology Evolution

Leading-edge technology

Tire Performance Improvement

More comfortable driving

Environmental performance

Naturally derived materials

Datasheet&Sample Available

For sample orders, please contact us here.

Made in Japan

Full use of advanced unexplored technology

Innovative environmental tires are required for mobility appropriate for an environmentally oriented society. We contribute to the production of tires for the new era that meet the needs of society, new regulations, and people’s sense of values.

Tire Environmental Issues

New Global Issue

Microplastic Problem

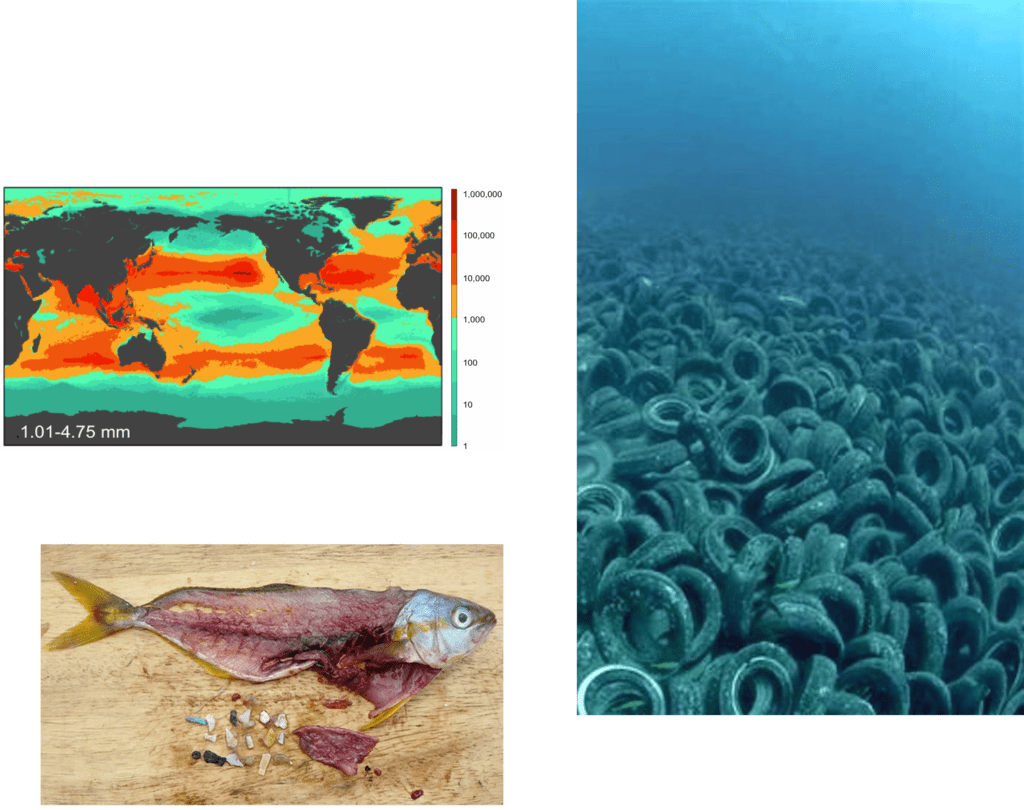

TRWP : Tire Road Wear Particles

Microplastics are microscopic plastic particles smaller than 5 mm; in 2018, the European and American Gastroenterological Associations announced that microplastic fragments are being taken up by humans via marine organisms.

Cause

Tire dust is the primary cause

It is reported that 80% of microplastics in the ocean originate from tires.

Microplastics

Regulation

Start of regulation in the EU

In Europe, there is a new trend to regulate them due to concerns about their impact on the environment.

NEWS

The European Commission has already indicated that it intends to establish new regulations for dust from tire wear.

OUR VISION

In 2040, the world's tires will be white again

Since Dr. Goodrich’s invention of the carbon black tire, the era of the black tire has lasted for over 100 years. We envision a future where by 2040 the world’s tires will once again be white and clean.

LIPPER (NR100-18)

Better Tire Performance

Tire performance and environmental performance can be improved by blending LIPPER (NR100-18), a bio-rubber reinforcing material, with cellulose nanofibers at 3% to 6% in the rubber compound for tires.

Strengths of the LIPPER (NR100-18)

Four key points of innovation in tires

It simultaneously achieves the durability required of tires, the reduction of power consumption required of electric mobility, the reduction of CO₂ emissions, and the reduction of environmental impact from tire wear dust.

Tire Innovation through Nanotechnology

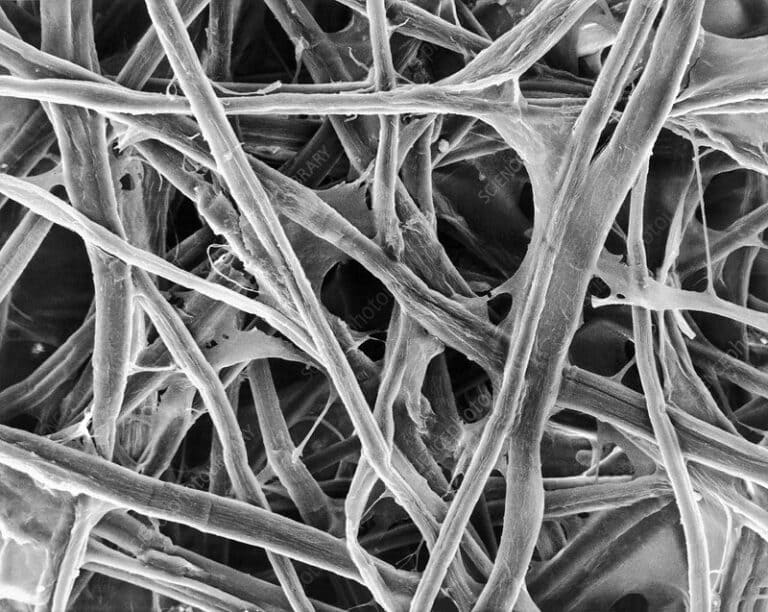

LIPPER (NR100-18) is a next-generation tire reinforcing material made from wood and using nanotechnology. It is a rubber reinforcing material with a high biomass content that can be added to natural and synthetic rubbers to improve rubber properties.

Technology for a Microscopic World

One nanometer is one millionth of a millimeter. Nanotechnology is the technology to control materials at the atomic and molecular scale, and the LIPPER (NR100-18) was created using this technology, which is considered to be a field that will develop significantly in the 21st century.

De-carbon black

Conventional technology has strengthened rubber by adding carbon black to natural or synthetic rubber; the use of LIPPER (NR100-18) strengthens the rubber and makes it possible to produce freely colored rubber products.

Datasheet &Sample Available

For sample orders, please contact us here.

LIPPER (NR100-18) tire performance

Running performance

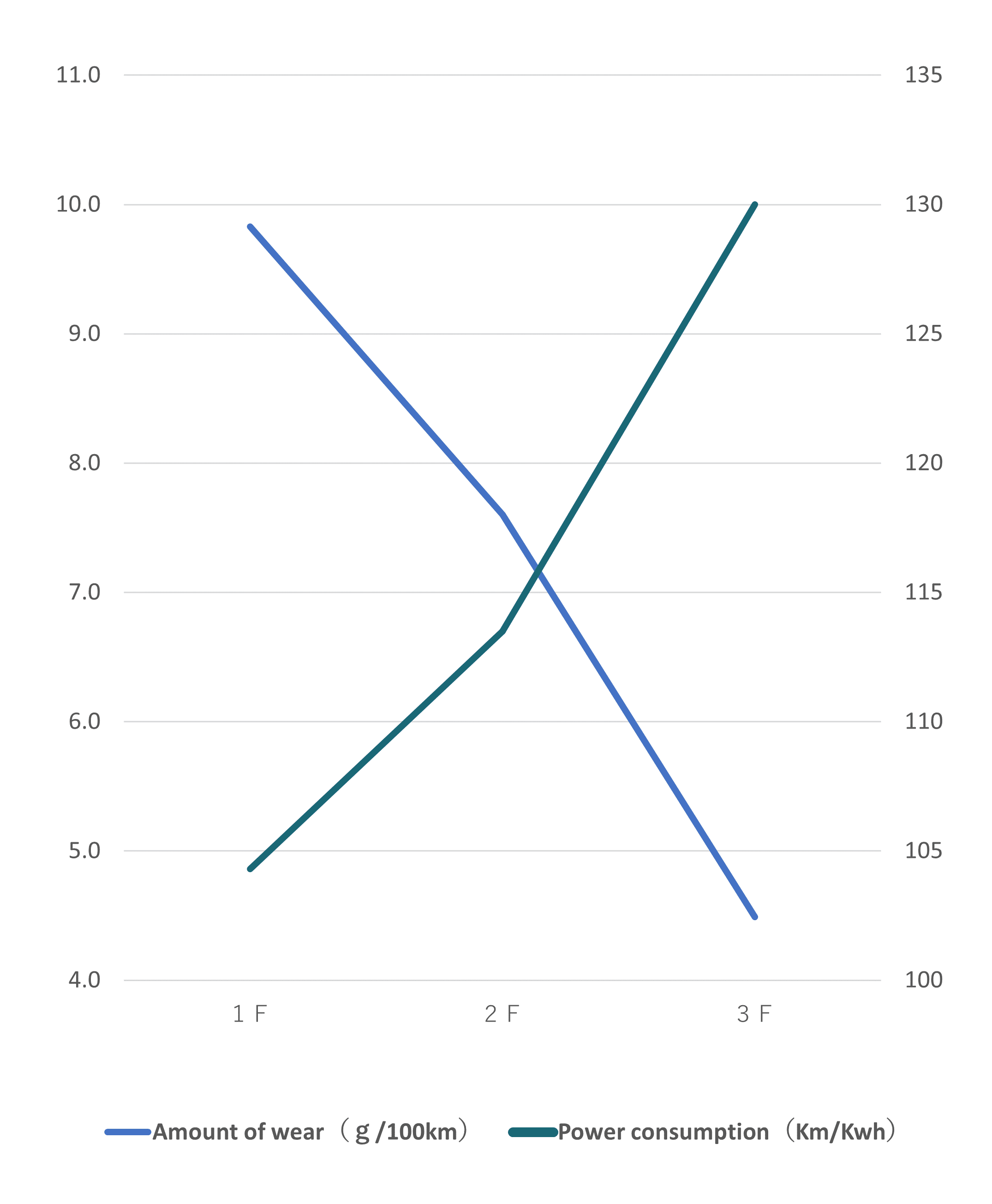

This is a driving test of a 5.5" E-scooter solid tires with 16% bio-rubber reinforcement LIPPER (NR100-18).

Tire Performance: Amount of wear and electric consumption

In running tests of 3F 5.5-inch E-scooter solid tires with 16% addition of this bio-rubber reinforcement, the amount of wear was reduced by about 50% and the driving range was increased by about 25%.

| Bio rubber reinforced material ratio | CNF ratio | |

|---|---|---|

| 1F | 0% | 0% |

| 2F | 8% | 3% |

| 3F | 16% | 6% |

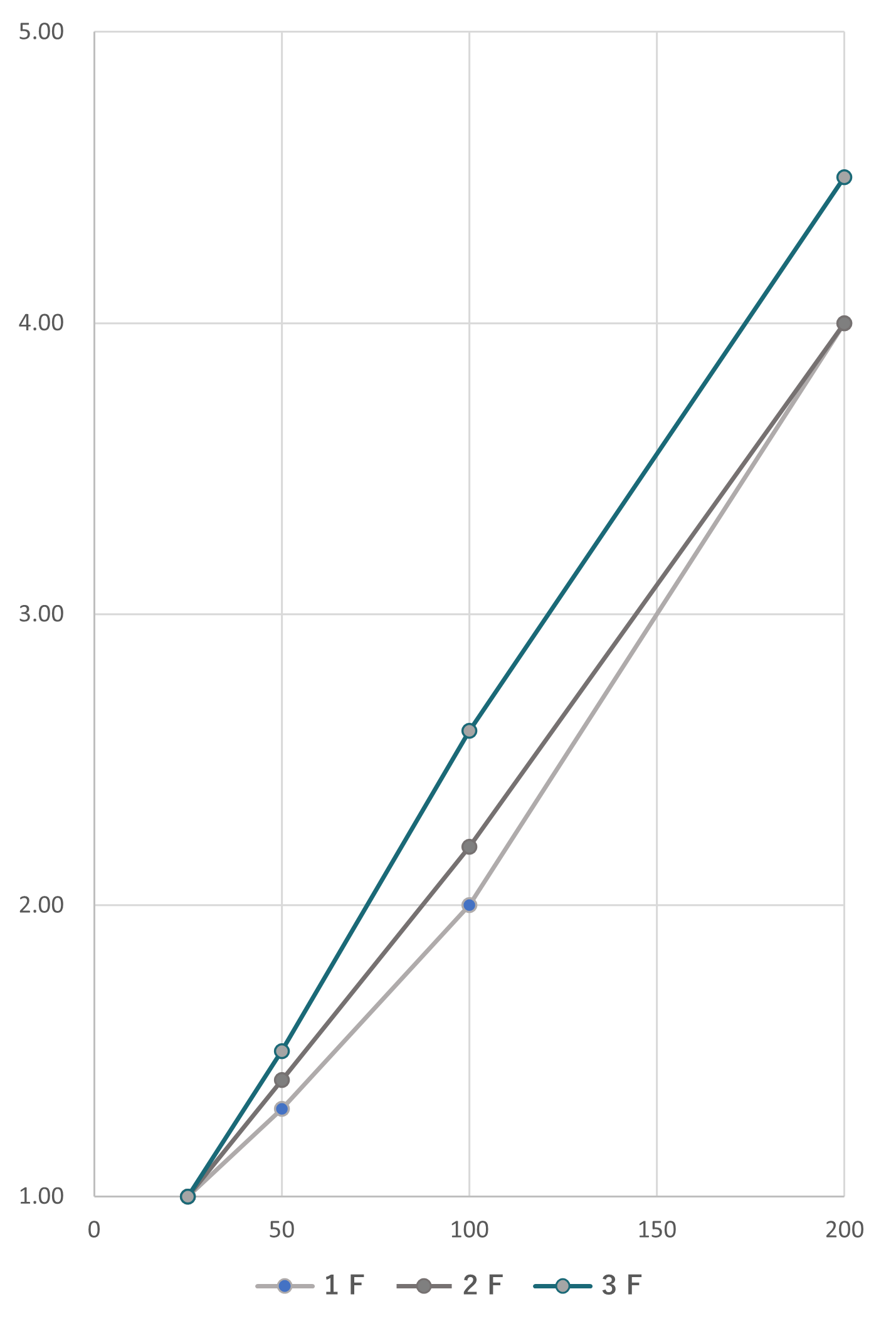

Rubber Performance: Tensile Strength

The resilience modulus is improved and compression set is reduced as shown in the table.

The LIPPER (NR100-18) maintains and improves the functional performance of tires while reducing the amount of petroleum-derived carbon black used.

| Bio rubber reinforced material ratio | CNF ratio | |

|---|---|---|

| 1F | 0% | 0% |

| 2F | 8% | 3% |

| 3F | 16% | 6% |

Innovating Tires for Micromobility

We provide materials for the best environmental tires for micromobility, which is gaining attention as a comfortable and safe mobility, as a clean vehicle, and as a tool for healthy and humane urban development.

<Main Application>

Bicycle tire

Wheelchair tire

E-scooter tire

We support your tire production to meet the needs of environmentally oriented people and society.

IMPACT

Protects rich marine resources and contributes to CO₂ reduction

LIPPER (NR100-18) is a tire with a high biomass material ratio, which makes it strong without petroleum-derived carbon black. It also reduces environmental impact by improving biodegradability of tire wear dust.

Reduction of environmental impact

CO₂ emissions are dramatically reduced simply by replacing cars with low-speed mobility tools for short trips.

Microplastics

80% reduction expected (5 million tons per year of tire dust)

CO₂ emissions

80% reduction expected (Percentage of carbon content in tire)

Natural Mobility

Use of environmental materials

We are challenging ourselves to utilize natural materials for structural members and tires.

Blend Example

Tires blended with LIPPER (NR100-18) will have an increased ratio of bio-materials and a significantly decreased ratio of petroleum-derived materials.

| Blend | Conventional tire | New Compound tire |

|---|---|---|

| Natural rubber | 60 | 35 |

| BR | 40 | 40 |

| LIPPER(NR100-18) | 0 | 32 |

| Carbon Black | 51 | 0 |

| Silica | 0 | 44 |

| Titanium dioxide | 0 | 5 |

| Oil | 15 | 15 |

| PEG | 5 | 5 |

| S169 | 0.5 | 0.5 |

| Coumarone G-90 | 10 | 10 |

| Zinc oxide | 5 | 5 |

| Stearic acid | 1 | 1 |

| Nocrac SP-N | 3 | 3 |

| Sunnoc | 1 | 1 |

| Sulfur | 2.1 | 2.1 |

| Nocceler MSA | 1.5 | 1.5 |

| Nocceler TS | 1.2 | 1.2 |

| Total | 201.3 | 201.3 |

Datasheet &Sample Available

For sample orders, please contact us here.

Environmental Compounding Ratio

| Environmental Indicators | Conventional tire | NR100-18 Compound tire |

|---|---|---|

| Biomaterials Ratio | 30% | 33% |

| Oil origin materials ratio | 56% | 20% |

| Organic materials ratio | 18% | 17% |

| Inorganic materials ratio | 6% | 30% |

Not only have the tires changed, but also the industry's level of responsibility for them has changed.

Matt Ross(Tire Technology International, Editor in Chief)

Global Goals

Contributions to the SDGS

We will contribute to the achievement of the SDGs by improving the environmental performance of tires.

Take urgent action to combat climate change and its impacts by regulating emissions and promoting developments in renewable energy

Goal 13 Feasible measures to combat climate changeConserve and sustainably use the oceans, seas and marine resources for sustainable development

Goal 14 Conserve the richness of oceanSustainability in the Value Chain

Environmentally Conscious Procurement

In procuring raw materials for tire production, we are committed to environmentally friendly procurement.

Actively use woody materials such as lumber left over, thinning, and house demolition

Do not use illegally logged timber

Ensure traceability

Actively use woody materials such as lumber left over from lumbering, thinning, and house demolition

Cooperate with "wood-related businesses registered under the Clean Wood Act

Sample Request

If you have any other questions, please contact us and we will reply within 24 hours.

Ensure sustainable consumption and production patterns

Goal 12 Responsible consumption and production