You are good

サステイナブル素材を使った

ネイチャーポジティブタイヤ

2026年5月発売予定

ESG

WEF 'Ocean Impact Navigator'による管理

新素材

革新的ナノテクノロジーの利用

クリーンな車

低燃費タイヤによる環境配慮

対応車種

当初対応予定の車種およびタイヤサイズです。

ラパン

155/65R14

Coming Soon

ムーヴキャンバス

165/65R14

Coming Soon

スペーシアギア

165/65R14

Coming Soon

ハスラー

165/65R14

Coming Soon

フレアクロスオーバー

165/65R14

Coming Soon

ヤリスクロス

215/50R18

Coming Soon

ヴェゼル

215/55R17

Coming Soon

ジムニーシエラ

195/80R15

Coming Soon

画像はイメージです。

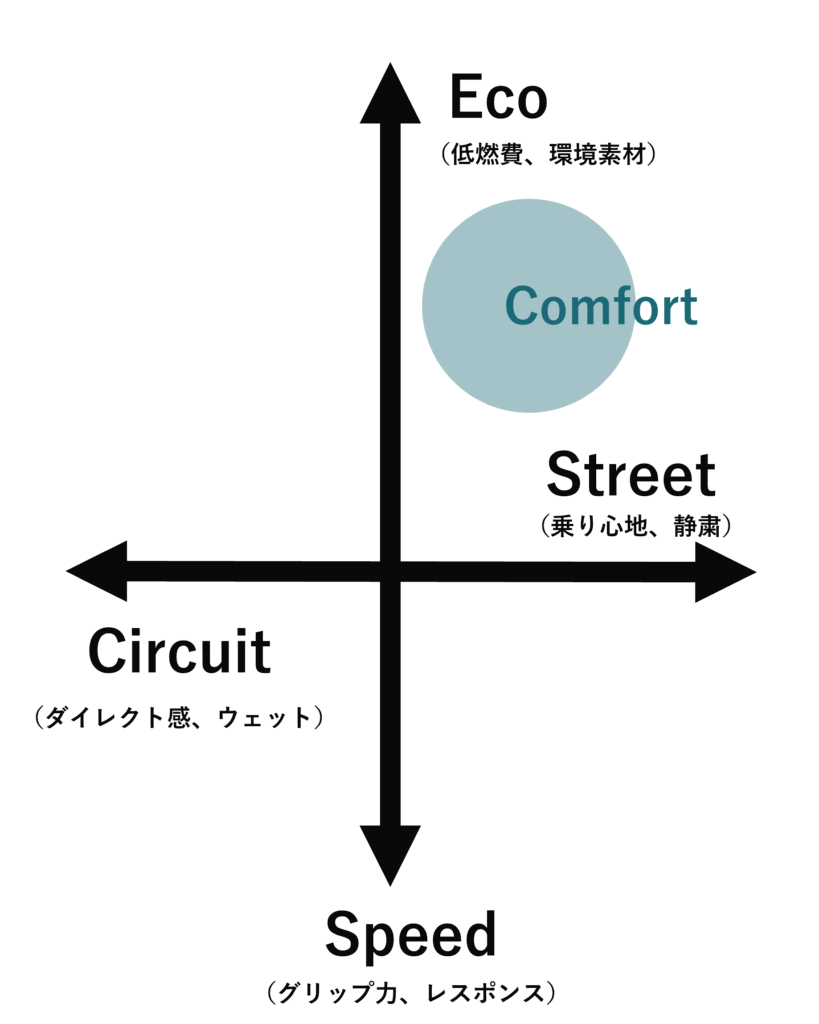

確実な走行性能

PREMIUM

特別先行予約

2026年5月3日スタート

日

時間

分

秒

メルマガ登録

最新情報はこちらで発信していきます。

FutureTech

未踏の先端技術に挑む

まだ十分に社会実装されていない先端技術を積極的に取り入れ、タイヤ開発に応用していきます。性能と環境性を高い次元で両立させ、持続可能なモビリティの未来を切り拓きます。

MIT Venture Forum Program of Japan

Clean Tech Open Global Ideas Pitch Award 🔗

Europe Long-term Program(JETRO) 🔗

Ocean Impact Organisation Boost

TechCrunch Startup Battlefield 🔗

Climate Tech Award (Climate Tech Ventures)

環境素材タイヤ

私たちのミッションは、サステイナブル素材によるタイヤ開発で革新をもたらすことです。

詳細情報の発表

セールに関する詳細情報をお知らせします。

2025年10月

予約開始

当サイトにて予約を受け付けを開始します。

2025年12月

製造開始

タイヤの走行実験を行い、耐摩耗性や電力消費などを確認しました。

2026年1月

出荷開始

順次発送します。

2026年5月

社会的課題

従来技術

これまでのタイヤ

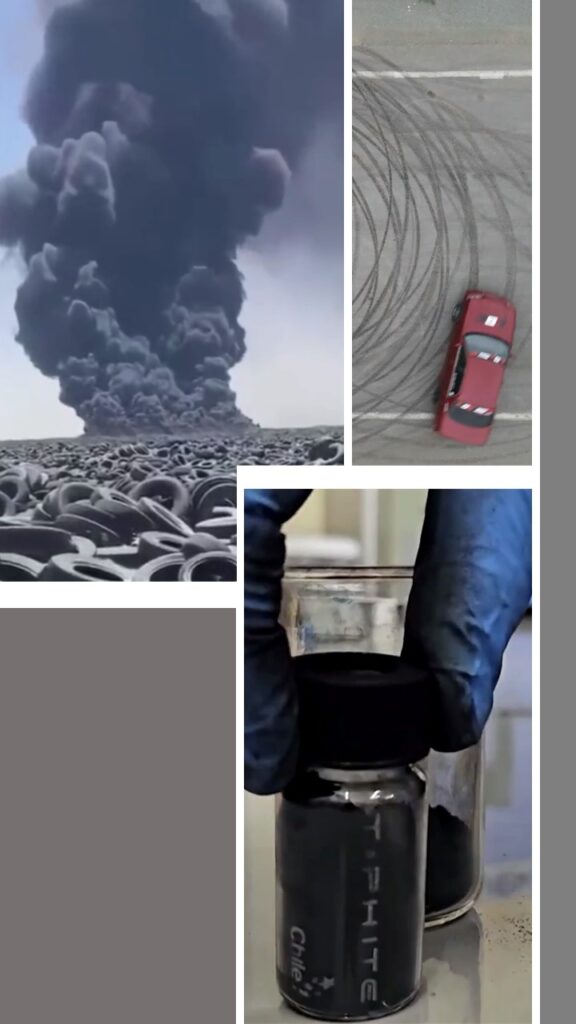

従来タイヤは有害物質を含む添加剤を使用し、製造・焼却過程で多量のCO₂を排出する点が大きな課題です。

新しい環境問題としてのタイヤ粉じん

タイヤ・路面摩耗粉じん(TRWP)が環境に与える影響は、新たな問題となっています。

0

%

マイクロプラスチック

タイヤ粉じん由来という報告があります。

0

種類

以上の材料がタイヤには必要

有害物質など環境負荷の多い物質も含まれている

解決策

タイヤの原材料を自然素材に変えることで、この問題を解決したいと考えています。

バイオテクノロジーによる

環境配慮タイヤ

有害物質を使わず再生資源を活用し、製造から廃棄までのCO₂排出を抑えた次世代型のタイヤ開発に取り組んでいます。

PREMIUM

特別先行予約

2026年5月3日スタート

日

時間

分

秒

メルマガ登録

最新情報はこちらで発信していきます。

タイヤの環境負荷を大幅に軽減することに期待

セシリア・タム(Futurity Systems CEO兼共同創業者)

LIPPERの「白いソリューション」は、まさに一筋の光のよう

ルノー・ヘーリンゲン(建築家、Rotor元プリンシパル)

バイオの世紀が始まる

バイオマス素材はここ15年ほど研究が盛んになりましたが、本番はまだまだこれからだと思います。

石油の世紀だった20世紀に対して、21世紀はバイオ素材の世紀になると考えています。

これから20年、30年かけて成長していく新しい技術領域です。

使用を減らしていきたいタイヤ添加剤

タイヤの性能を支える多様な添加剤は、安全性や耐久性に寄与する一方で、発がん性や環境汚染の要因となる物質も含まれています。

-

6PPD老化防止剤 🔗

酸化防止のために使用されますが、分解生成物が水生生物に強い毒性を示すことが報告されています。

-

カーボンブラック強化材

発がん性の懸念があり、微細な粉じんとして飛散することで呼吸器など健康被害の要因となります。

-

RFL接着剤

レゾルシノールは皮膚刺激や発がん性懸念があり、RFL接着剤で使用され環境への毒性も問題視されています。

-

TBBS加硫促進剤

加熱や反応でニトロソアミンを生成し、発がん性リスクが指摘されています。

-

芳香族オイル可塑剤

多環芳香族炭化水素を含み、環境汚染や人体へのリスクが国際的にも指摘されています。

Made in Japan

次世代タイヤへの素材革新

私たちは従来添加剤の使用を減らし、環境負荷を抑えた先端素材へ切り替えていく方針です。

WAVES ビジネスプランコンテスト最優秀賞

GX分野スタートアップピッチコンテスト審査委員会賞

マリンテックグランプリ最優秀賞・テラル賞

Industry-Up Business Contest ファイナリスト

Monozukuri Hardware Cup

対応車種

当初対応予定の車種およびタイヤサイズです。

ソリオ

165/65R15

Coming Soon

フリード

185/65R15

Coming Soon

シエンタ

185/60R15

Coming Soon

C-HR

225/50R18

Coming Soon

CX-3

215/50R18

Coming Soon

エクストレイル

225/60R18

Coming Soon

フォレスター

225/60R17

Coming Soon

画像はイメージです。

PREMIUM

特別先行予約

2026年5月3日スタート

日

時間

分

秒

メルマガ登録

最新情報はこちらで発信していきます。

よくある質問

不明な点は、お問い合わせフォームからご連絡ください。

購入時点のタイヤについては、無料で取り付けまで行います。当社指定の自動車整備会社に車で行っていただき、そこで新しいタイヤと交換します。

装着方法は通常のタイヤを同じです。

送料は無料です。

1年間のメーカー保証期間を設けております。当社にて送料を負担した上で商品の交換対応を行います(お客様の故意・過失等で生じた故障は除きます)。

所有している車のタイヤ側面をご覧ください。

(例)155/65R14

195/65R15

225/60R17

どのタイヤにも必ず上記のようなサイズ情報が記載されていますので、ご確認ください。

自然素材を使っているため、自然の変化として経年で色が濃くなっていくことがあります。