FutureTech

Fully leveraging cutting-edge frontier technologies

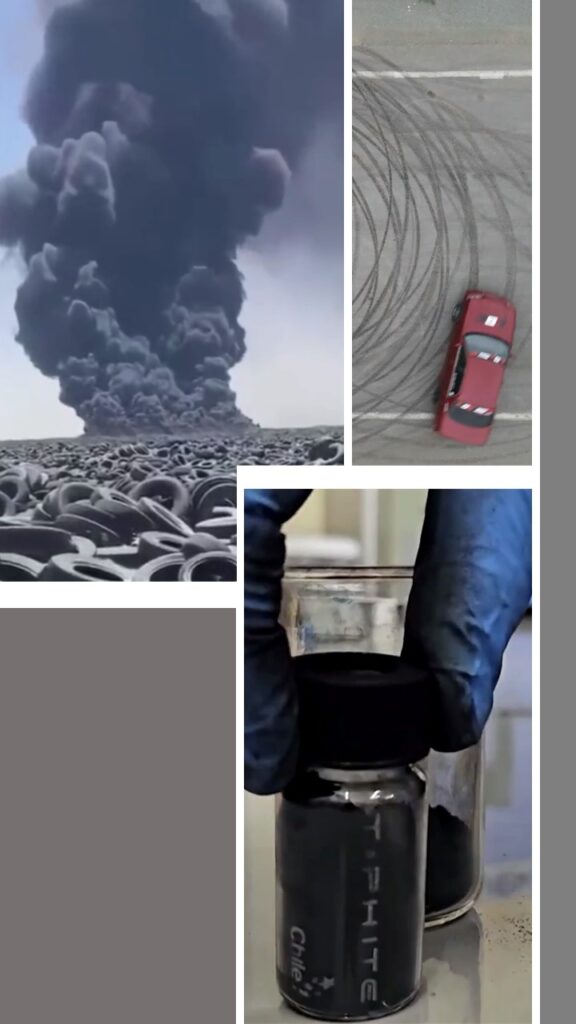

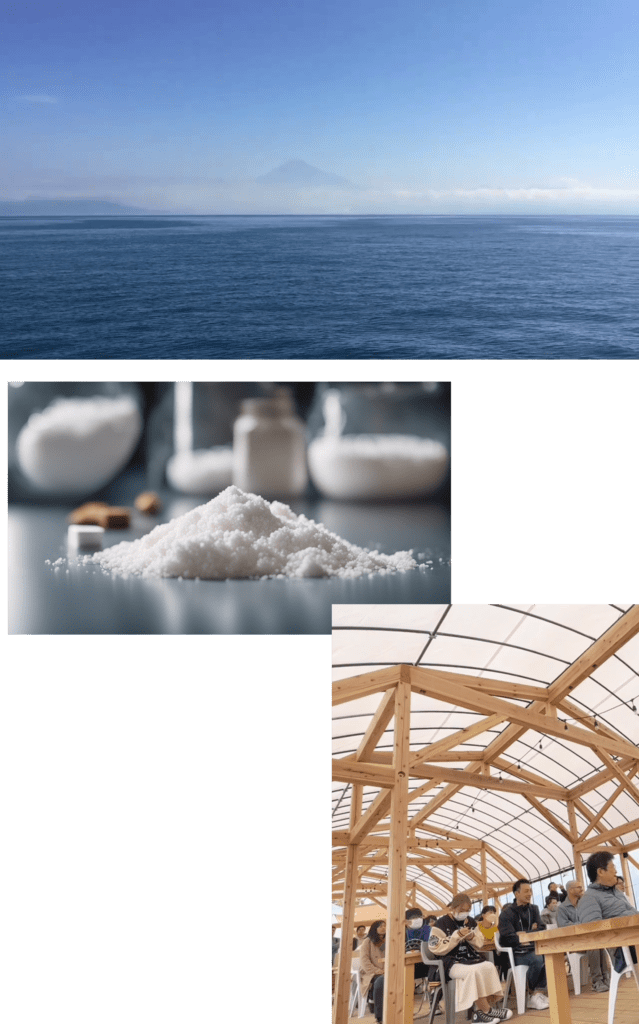

We will actively incorporate cutting-edge technologies that have not yet been fully implemented in society and apply them to tire development. We will achieve a high level of performance and environmental compatibility, paving the way for a sustainable mobility future.

MIT Venture Forum Program of Japan

Clean Tech Open Global Ideas Pitch Award 🔗

Europe Long-term Program(JETRO) 🔗

Ocean Impact Organisation Boost

TechCrunch Startup Battlefield 🔗

Climate Tech Award (Climate Tech Ventures)